Methods and systems

A variety of cleaning methods are used, depending on the type of workpieces, contamination, requirements for component cleanliness and cleaning times within the production process.

Wet chemical cleaning – the most common method

- Blast cleaning – high pressure loosens and washes away the dirt

- Immersion cleaning – the preferred method for complex geometries

- Injection flood washing – strong currents in the cleaning bath

- Ultrasonic cleaning – sound pressure blasts away the dirt

Blast cleaning – with solid and liquid media

- Compressed air method – various blasting media remove deposits

- Airless blast cleaning – for workpieces with easily accessible surfaces

- High-pressure water jetting – cleaning and deburring in a single operation

- Blasting with carbon dioxide – cleans complete components or defined areas

Alternative cleaning methods

- Laser cleaning – shock waves for degreasing, decoating and pre-treatment

- Plasma cleaning – for parts made of different materials and complicated geometries

- Vibration cleaning – vibrations remove liquid and solid dirt

A combination of various cleaning processes may be the ideal solution in regard to cleanliness and efficiency, depending on the task at hand

Wet chemical cleaning

Wet chemical cleaning by means of aqueous media or solvents is the most commonly used technology in industry. Various system concepts are available for this purpose, among them single-chamber systems, in-line immersion systems and continuous flow systems. Physical processes are used at different intensities to help detach contaminants from the parts and to shorten the cleaning time, including blasting, immersion, injection flooding and ultrasound.

Blast and immersion cleaning

Blast cleaning – high pressure loosens and washes away the dirt

In blast cleaning, the medium is sprayed through nozzles onto the cleaning surface at high pressure. During the process, some of the contamination is dissolved or emulsified by the chemical action of the medium and others are washed away by the high kinetic energy of the spray jet. The effects are highly dependent on the shape and arrangement of the nozzles and on the strength of the spray.

Immersion cleaning – the preferred method for complex geometries

Immersion cleaning is usually the method of choice for the cleaning of parts with complex geometry, for example with blind holes or undercuts. The chemical action of the cleaning medium causes adhering dirt to detach when the workpiece is immersed in the cleaning bath. Rotating or swivelling the parts in the bath increases the cleaning effect.

Injection flooding and ultrasonic cleaning

Injection flood washing – strong currents in the cleaning bath

In injection flooding, pumps draw liquid from the cleaning bath and then force it back in at high pressure through a nozzle system located below the liquid level. This creates powerful currents in the bath that produce turbulence on the component edges that loosens the contamination. The flow of liquid past blind holes and undercuts also induces a suction effect which “pulls” the dirt out from inside.

Ultrasonic cleaning – sound pressure blasts away the dirt

Ultrasonic cleaning is also used in a cleaning bath. It is based on the physical effect of cavitation: an ultrasound generator produces electric signals in a specific frequency which are transmitted into the liquid as sound waves by means of rod or surface transducers. The sound pressure is characterised by alternating negative and positive pressure. Microscopically small cavities are created by the high intensity. They implode during the subsequent positive pressure phase, producing shock waves with considerable energy density. This creates micro-currents in the liquid that “blast” contamination off the components and wash them away from the workpieces.

The frequency of the sound waves is decisive for the cleaning effect. The lower the frequency, the larger the cavitation bubbles and the greater the energy they release.

Blast cleaning – with solid and liquid media

The cleaning effect in blasting processes is largely based on the mechanical energy and the more or less strong abrasiveness of the solid abrasive, which is accelerated onto the cleaning surface. The processes are also suitable for deburring, smoothing, roughening or matting the surfaces, depending on the method and blasting medium. Frequently used blast methods include:

Compressed air and airless blast cleaning methods

Compressed air method – various blasting media remove deposits

Compressed air blasting is carried out with a wide variety of abrasives that are applied to the cleaning surface at high speed through a nozzle. The method can be used to remove various contaminants such as deposits, corrosion, scaling and paint. The abrasion rate is decisively influenced by the abrasive composition, the blasting angle, the geometry of the nozzle at the outlet and its distance from the component. An additional cleaning step is often required to remove any blasting agent that may have remained on the cleaned material.

Airless blast cleaning – for workpieces with easily accessible surfaces

The airless blast cleaning method can be used to clean workpieces with easily accessible surfaces such as plates, flat beams, cast and rolled steel products as well as pourable parts. In this case, the abrasive agent is applied evenly onto the surface using paddle wheels. The energy transferred during impact causes the abrasive agent to remove contamination, deposits, corrosion, scaling and coatings.

Blasting with high pressure and carbon dioxide

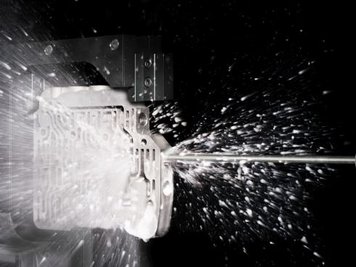

High-pressure water jetting – cleaning and deburring in a single operation

High-pressure water jetting enables the simultaneous cleaning and deburring of workpieces. Nozzles are used to direct the water jet onto the areas of a workpiece to be treated at pressures of between 300 and 1,100 bar or higher, cleaning even barely accessible intersections and bores. The high kinetic energy of the water jet removes burrs from the machined edges, along with chips and other contaminants. Suitable chemicals can be added to enhance the cleaning effect.

Airless blast cleaning – for workpieces with easily accessible surfaces

The airless blast cleaning method can be used to clean workpieces with easily accessible surfaces such as plates, flat beams, cast and rolled steel products as well as pourable parts. In this case, the abrasive agent is applied evenly onto the surface using paddle wheels. The energy transferred during impact causes the abrasive agent to remove contamination, deposits, corrosion, scaling and coatings.

The cleaning effect in both is based on a combination of mechanical action as a blasting agent, thermal effects (embrittlement of contaminants and generation of stresses between the contaminant and the surface due to the introduction of cold) and “explosive” evaporation of the solid carbon dioxide striking the surface (sublimation). The CO2 completely changes into its gaseous state under ambient conditions, so no blasting agent residues remain on the component that would have to be removed separately.

Alternative cleaning methods – leaser, plasma and vibration cleaning

Laser cleaning – shock waves for degreasing, decoating and pre-treatment

Laser cleaning uses a powerful, focused laser beam as the cleaning medium, which is directed across the cleaning surface. The light energy from the laser beam is converted into thermal energy during the process, which causes layered (filmic) contaminants to be vaporised abruptly. Shock waves occur as a second effect. They cause particles to detach that cannot be evaporated due to their characteristics and size. The method can be used for degreasing, decoating and pre-treatment prior to bonding and coating metals, plastics and industrial ceramics.

Plasma cleaning – for parts made of different materials and complicated geometries

Plasma cleaning can be used to treat parts made of different materials, either as a batch process or individually. In the process, non-polar contaminants are removed even from complicated geometries with tight radii, undercuts, bores and slots. Plasma is a gaseous mix of atoms, molecules, ions and free electrons. A variety of plasma gases can be used to clean and activate or functionalise the surface simultaneously, depending on the case at hand.

Vibration cleaning – vibrations remove liquid and solid dirt

Vibration cleaning removes contaminants from parts by vibrating them in the frequency range of 20 to 100 Hertz, which breaks their adhesion force. The method can be used to clean off liquid and solid contaminants such as oils, cooling lubricants, chips and particulate matter.